Versatile and gentle

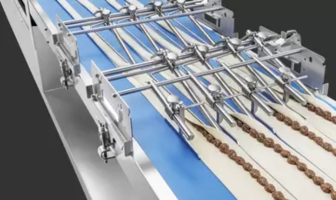

- Guillotine that can be moved along the line: Production of a wide variety of products in a confined space

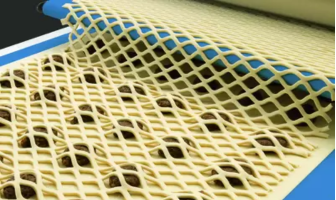

- For all types of dough, even shortcrust or thin dough

- Folding, rolling, filling, decorating, cutting, stamping: anything is possible

Configurable to suit your needs

- Compact and configurable automated solution

- 3 different lengths

- 2 conveyor belt directions

- Mobile: easy to move

Operation via touch panel

- Simple to operate, even for semi-skilled workers

- Glass membrane keypad with clear, language-independent icons

- Up to 99 products can be saved in the memory

Expandable and future-proof

- Versatile and easy to combine: Plug & play

- Additional automated processes can be added using up to 4 motor-driven accessories

- Robust, durable design without appearing bulky

Hygiene made easy

- Sophisticated hygienic design

- Smooth surfaces, stainless steel construction

- Materials certified for food production

- Compliant with hygiene standard UL Sanitation